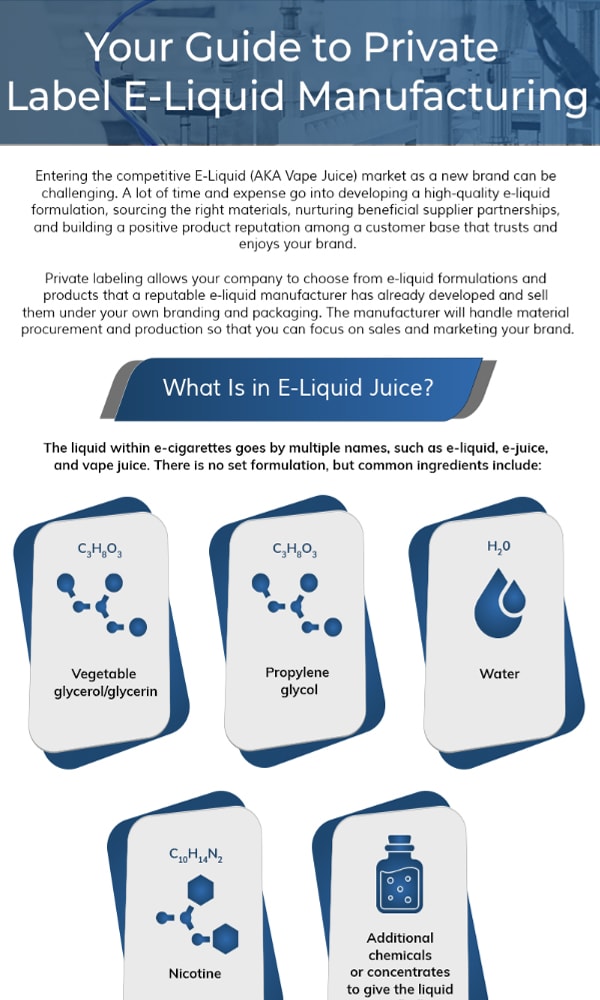

What Is in E-Liquid Juice?

The liquid within e-cigarettes goes by multiple names, such as e-liquid, e-juice, and vape juice. There is no set formulation, but common ingredients include:

Vegetable glycerol/glycerin

Propylene glycol

Water

Nicotine

Additional chemicals or concentrates to give the liquid a specific flavor

E-liquid formulations can also contain varying amounts of the above. For example, e-liquids can be nicotine-free or they can contain low to high amounts of the substance, depending on your preference.